June 27, 2024

When choosing materials for various applications, it is crucial to understand the properties and differences between polycarbonate and corrugated polycarbonate sheets. Both materials offer unique advantages, making them suitable for specific uses. This blog aims to provide an in-depth comparison between polycarbonate and corrugated plastic, helping professional buyers and global distributors make informed decisions.

Is Polycarbonate More Durable and Weather-Resistant Than Corrugated Plastic?

Impact Resistance

Polycarbonate is renowned for its high impact resistance, making it nearly unbreakable under normal conditions. This property makes it an excellent choice for applications where durability and safety are paramount. For instance, polycarbonate can withstand impacts from debris during storms, making it suitable for use in protective barriers and outdoor structures.

Corrugated plastic, while strong, does not match the impact resistance of polycarbonate. Its fluted design offers good rigidity, but it can be punctured or damaged under heavy impact. Therefore, it is less suitable for high-impact applications but remains an excellent choice for lightweight and temporary uses.

Weather Resistance

Polycarbonate exhibits superior weather resistance compared to corrugated polycarbonate sheets. Polycarbonate also maintains its structural integrity in extreme temperatures, both hot and cold, ensuring long-term performance in various climates.

Corrugated plastic is also weather-resistant but to a lesser degree. It performs well in outdoor environments, resisting water and chemicals, but it can become brittle over time when exposed to prolonged UV radiation. For short-term or seasonal outdoor applications, corrugated plastic is a cost-effective solution.

What Are the Differences in Transparency and Aesthetic Versatility Between Polycarbonate and Corrugated Plastic?

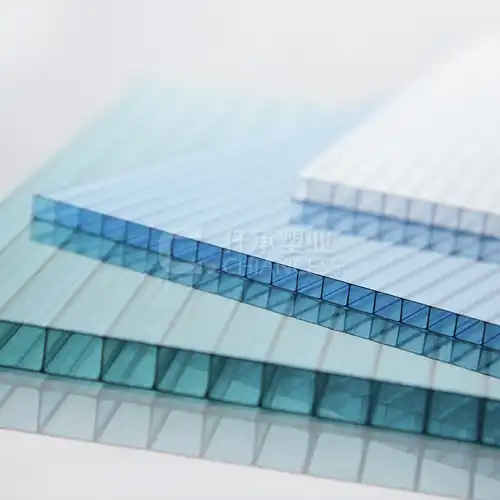

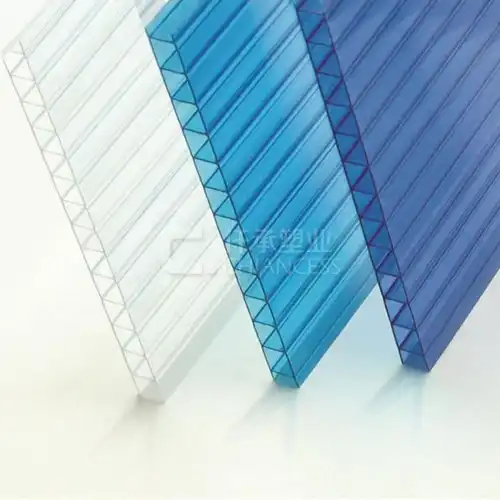

Visual Clarity

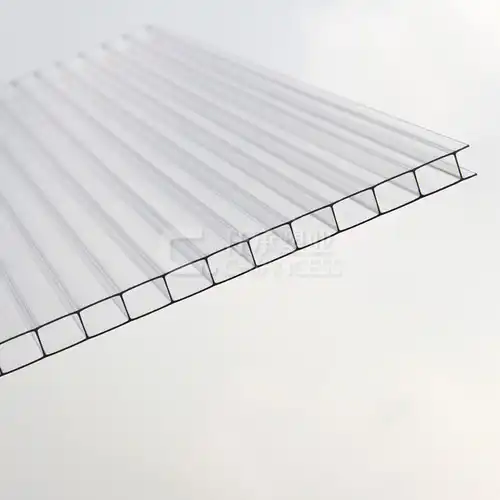

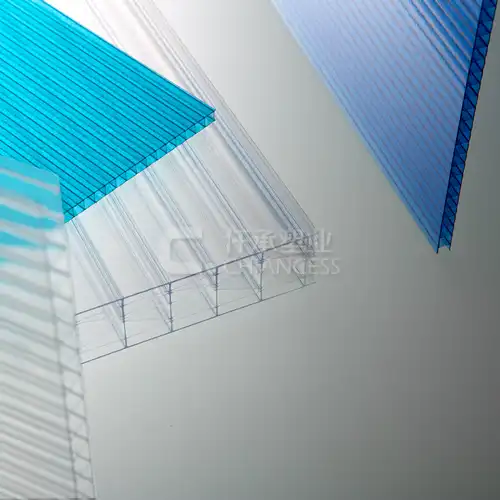

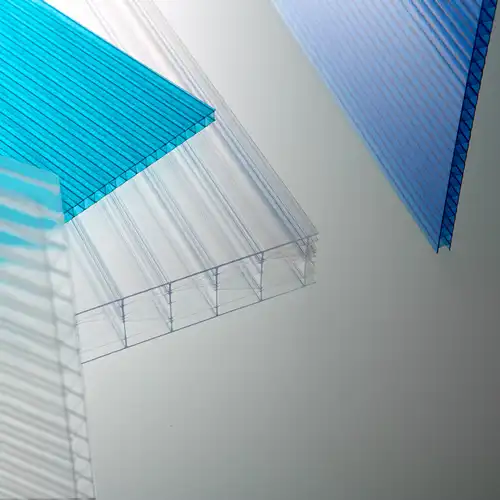

One of the key advantages of polycarbonate is its exceptional transparency. It transmits light almost as effectively as glass, making it a preferred choice for applications requiring clear visibility. This clarity is beneficial for greenhouses, skylights, and protective screens where light transmission is crucial.

Corrugated plastic, on the other hand, is generally opaque or translucent, depending on its color and thickness. While it can be produced in various colors and can be semi-transparent, it does not provide the same level of visual clarity as polycarbonate. Therefore, it is more commonly used in applications where transparency is not a primary concern.

Aesthetic Versatility

Polycarbonate's aesthetic versatility allows it to be used in a variety of design applications. It can be easily shaped and molded, offering designers flexibility in creating innovative structures. Additionally, polycarbonate is available in different colors and finishes, including UV-resistant coatings that enhance its appearance and longevity.

Corrugated plastic offers limited aesthetic versatility compared to polycarbonate. It is primarily valued for its practicality and cost-effectiveness rather than its visual appeal. However, it can be printed with high-quality graphics, making it suitable for signage and advertising purposes.

Is Polycarbonate More Cost-Effective Than Corrugated Plastic in the Long Run?

Initial Cost

Polycarbonate tends to be more expensive than corrugated plastic due to its superior properties and versatility. The higher initial cost can be justified by its long-term durability, impact resistance, and aesthetic qualities. For applications where these factors are critical, the investment in polycarbonate can provide significant returns over time.

Corrugated polycarbonate sheets are a more budget-friendly option, making it ideal for temporary or short-term applications. Its lower cost makes it accessible for projects with limited budgets or where the material will only be used for a short duration.

Long-Term Value

When evaluating the cost-effectiveness of these materials, it is essential to consider their long-term value. Polycarbonate's durability and weather resistance mean fewer replacements and lower maintenance costs over time. This longevity can make it a more cost-effective choice in applications requiring long-term performance and reliability.

Corrugated plastic, while less durable, offers excellent value for temporary and short-term projects. Its low cost and ease of use make it a practical choice for applications where frequent replacement is not an issue.

How Do Polycarbonate and Corrugated Plastic Differ in Their Environmental Impact?

Recyclability

Both polycarbonate and corrugated plastic are recyclable, but the recycling processes and availability of recycling facilities can differ. Polycarbonate can be recycled into various products, including new polycarbonate sheets, reducing its environmental impact. However, the recycling process for polycarbonate is more complex and less widely available than for other plastics.

Corrugated plastic is also recyclable and can be processed through standard polypropylene recycling streams. Its recyclability makes it an environmentally friendly option for applications where the material will be disposed of after short-term use.

Environmental Considerations

In terms of environmental impact, polycarbonate has a higher carbon footprint during its production due to the energy-intensive manufacturing process. However, its long lifespan and recyclability can mitigate this impact over time. For environmentally conscious projects, considering the entire lifecycle of the material is essential.

Corrugated plastic's lower production energy requirement and recyclability make it a more environmentally friendly option for short-term use. Its lightweight nature also reduces transportation emissions, contributing to its overall lower environmental impact.

Is Polycarbonate or Corrugated Plastic Easier to Install and Handle?

Weight and Handling

Polycarbonate, despite its strength, is relatively lightweight compared to glass. This property makes it easier to handle and install, especially in large sheets. Its flexibility allows for easy cutting and shaping on-site, providing versatility during installation.

Corrugated plastic is even lighter than polycarbonate, making it extremely easy to handle and transport. Its lightweight nature reduces labor costs and installation time, particularly for large projects or temporary setups. This ease of handling is a significant advantage in applications where speed and efficiency are critical.

Installation Complexity

The installation of polycarbonate can be more complex than corrugated plastic due to its rigidity and the need for precise cutting and fitting. Specialized tools and expertise may be required to ensure proper installation and performance. However, once installed, polycarbonate provides a robust and durable solution.

corrugated polycarbonate sheets are straightforward to install, often requiring minimal tools and expertise. Its flexibility allows it to be easily cut and fitted into various shapes and sizes, making it ideal for DIY projects and applications where quick installation is necessary.

How Are Polycarbonate and Corrugated Plastic Used in Real-World Applications?

Polycarbonate in Architecture

A notable example of polycarbonate's use in architecture is the Eden Project in Cornwall, England. The biomes of the Eden Project are covered with hexagonal panels of polycarbonate, providing a lightweight, durable, and transparent covering that allows for optimal light transmission and insulation. The choice of polycarbonate was driven by its strength, weather resistance, and ability to create an aesthetically pleasing and functional structure.

Corrugated Plastic in Signage

During political campaigns, corrugated plastic signs are ubiquitous. Their low cost, ease of printing, and lightweight nature make them ideal for producing large quantities of signs quickly. After the campaign, these signs can be recycled, demonstrating the practicality and environmental benefits of corrugated plastic for short-term use.

Conclusion

In conclusion, both polycarbonate and corrugated polycarbonate sheets offer unique advantages depending on the application. Understanding the specific needs of your project and weighing the properties and costs of each material will help in making an informed decision. Whether you prioritize durability, cost, or environmental impact, both materials provide valuable solutions for a wide range of applications. If you want to learn more about product, welcome to contact us: simon@chiancess.com

References

1. Chen, X., Li, L., & Zhou, X. (2012). Impact Resistance and Thermal Stability of Polycarbonate. Journal of Applied Polymer Science, 125(2), 1023-1030.

2. Al-Oqla, F. M., & Sapuan, S. M. (2014). Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm

3. Hsiao, S. W., Yang, S. Y., & Wang, L. C. (2015). Lightweight corrugated polypropylene panels for greenhouse applications. *Construction and Building Materials, 79*, 191-197.

4. Kim, J. R., Kim, H. S., & Lee, K. S. (2016). Impact resistance and energy absorption of corrugated polypropylene boards. *Composite Structures, 141*, 195-204.

5. Kuciel, S., & Kufel, L. (2018). Experimental investigation of the thermal insulation properties of multi-wall polycarbonate sheets. *Energy and Buildings, 158*, 1167-1174.

6. Lee, K. J., & Kim, H. K. (2017). Impact behavior of corrugated polypropylene sheets under high-velocity impact loading. *International Journal of Impact Engineering, 101*, 27-35.

7. Liu, D., He, L., & Wang, Z. (2017). Fabrication and properties of lightweight corrugated polypropylene panels with controllable thermal insulation. *Journal of Materials Science, 52*(14), 8489-8498.

.webp)