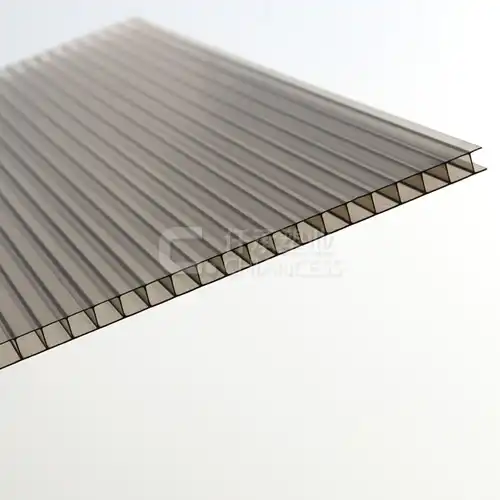

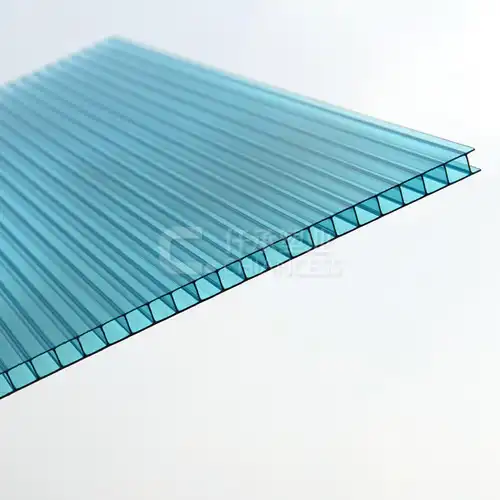

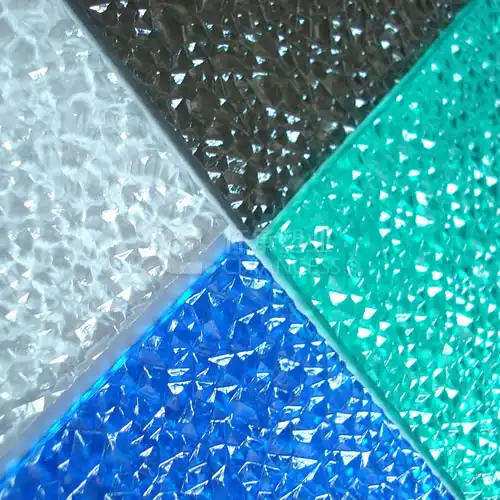

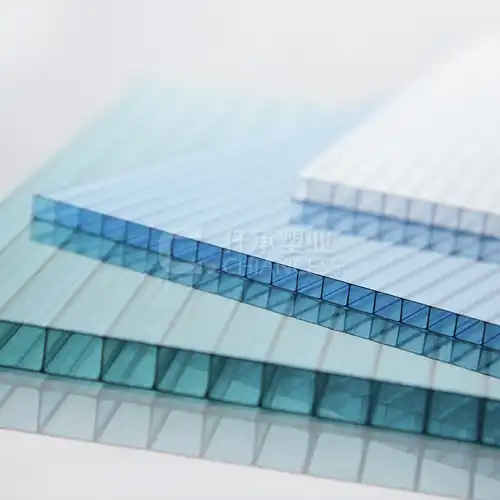

Due to their exceptional durability and adaptability, Colored polycarbonate solid sheet have emerged as a preferred material across a variety of industries. Due to their reputation for impact resistance, these sheets are suitable for demanding construction, signage, and DIY projects alike. They are able to withstand severe weather conditions without cracking or breaking because of their sturdy construction, providing dependable performance for extended periods of time.

Recognizing colored polycarbonate sheets' high resistance to UV radiation, which helps maintain their optical clarity and color stability over time, is essential to comprehending their durability. This UV resistance prevents brittleness and yellowing, ensuring longevity even in outdoor settings with constant sunlight.

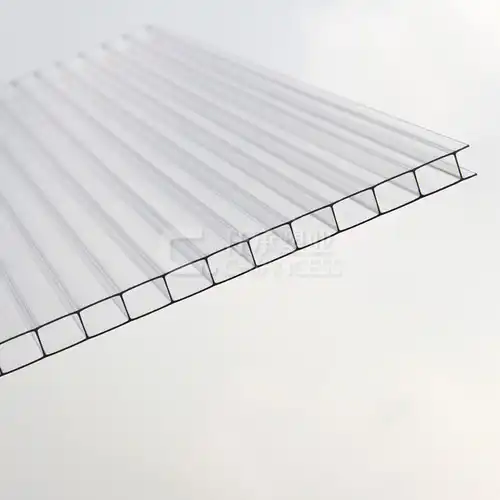

In addition, the lightweight idea of polycarbonate sheets works with more straightforward taking care of and establishment, adding to their far and wide use in different underlying and enlivening applications. Upkeep is direct, ordinarily requiring routine cleaning to eliminate soil and flotsam and jetsam, along these lines protecting their tasteful allure and execution.

Are Colored Polycarbonate Sheets UV Resistant?

Colored polycarbonate solid sheet must have good UV resistance, especially if they are going to be used outdoors where they will be exposed to sunlight. UV stabilizers are incorporated into the manufacturing process by manufacturers and protective coatings are applied after production by manufacturers. These actions actually alleviate the harming impacts of UV radiation, forestalling staining, yellowing, and corruption over the long haul.

Understanding the degree of UV assurance given by shaded polycarbonate sheets is fundamental for picking the fitting item founded on unambiguous undertaking necessities. For applications where prolonged sunlight exposure is anticipated, sheets with higher UV resistance ratings are preferred to ensure long-term clarity and durability. These sheets last longer and look better with regular care, like cleaning them to get rid of dirt and debris that can make UV damage worse.

Designers and builders can use colored polycarbonate sheets with sufficient UV resistance in a variety of outdoor applications, such as roofing, skylights, canopies, and architectural glazing, with confidence that they will maintain their visual integrity and performance over time.

What is the Impact Resistance of Colored Polycarbonate Sheets?

Another critical aspect of durability is impact resistance. Colored polycarbonate sheets are known for their exceptional strength, which makes them resistant to impact and breakage. This characteristic is particularly advantageous in applications where protection against hail, falling branches, or vandalism is necessary. Exploring the impact resistance ratings and real-world performance can provide insights into how well these sheets can endure harsh conditions without damage.

How Do Colored Polycarbonate Sheets Perform in Different Climates?

Climate variability can significantly affect the performance of building materials, including Colored polycarbonate solid sheet. These sheets are designed to withstand a wide range of temperatures, from freezing winters to scorching summers. Understanding their thermal expansion properties, as well as how they handle moisture and humidity, is crucial for ensuring long-term durability and stability in diverse environmental conditions.

Colored polycarbonate sheets are engineered to combine the aesthetic appeal of color with the robust properties of polycarbonate. When considering their durability, factors such as UV resistance, impact resistance, and suitability for different climates play pivotal roles.

UV Resistance and Its Importance

UV resistance is a critical factor in determining the lifespan of Colored polycarbonate solid sheet, especially when used outdoors. UV radiation from sunlight can cause materials to degrade over time, leading to discoloration, brittleness, and reduced structural integrity. Manufacturers address this issue by incorporating UV stabilizers into the polycarbonate resin or applying protective coatings on the surface of the sheets.

Most high-quality colored polycarbonate sheets are engineered to offer excellent UV protection, often with warranties that guarantee minimal discoloration or yellowing over extended periods of exposure. These sheets are commonly used in applications such as skylights, canopies, and greenhouse panels, where prolonged sunlight exposure is unavoidable.

Impact Resistance: Strength Under Pressure

One of the standout features of polycarbonate sheets, including the colored variants, is their exceptional impact resistance. Unlike glass or acrylic, which can shatter upon impact, polycarbonate sheets are highly durable and can withstand considerable force without breaking. This property makes them ideal for applications requiring protection against hail, storm debris, or accidental impacts.

The impact resistance of colored polycarbonate sheets is often tested and rated according to industry standards. Manufacturers provide data on the sheet's ability to resist impact at different speeds and forces, giving consumers confidence in their durability. For construction projects, this durability translates into long-lasting performance and reduced maintenance costs over time.

Performance in Different Climates

The durability of Colored polycarbonate solid sheet is further enhanced by their ability to perform well in diverse climatic conditions. From extreme cold to intense heat, these sheets maintain their structural integrity without warping, cracking, or becoming brittle. This resilience is due to the inherent properties of polycarbonate, which include a high coefficient of thermal expansion and contraction.

In regions with fluctuating weather patterns, such as coastal areas or mountainous regions, the ability of colored polycarbonate sheets to adapt to temperature changes is a significant advantage. Proper installation techniques, including allowance for thermal expansion, ensure that the sheets remain secure and stable over time. Additionally, their resistance to moisture absorption prevents issues such as mold growth or dimensional changes that can compromise durability.

Conclusion

Colored polycarbonate sheets offer a blend of durability, aesthetic appeal, and versatility that makes them suitable for a wide range of applications. Whether used in architectural glazing, signage, or DIY projects, these sheets are designed to withstand the rigors of daily use and environmental exposure. By understanding their UV resistance, impact resistance, and performance in different climates, consumers can make informed choices that meet their specific project requirements.

For those interested in exploring the benefits of colored polycarbonate sheets further or looking to integrate them into their projects, feel free to contact us at: simon@chiancess.com.

.webp)