Polycarbonate is a flexible fabric known for its quality, toughness, and transparency.One of the common request around tinted polycarbonate is whether it can be tinted.In this article, I'll dig into the conceivable outcomes of tinting polycarbonate, its applications, the forms included, and the benefits it offers.

What is Polycarbonate and Why Tint It?

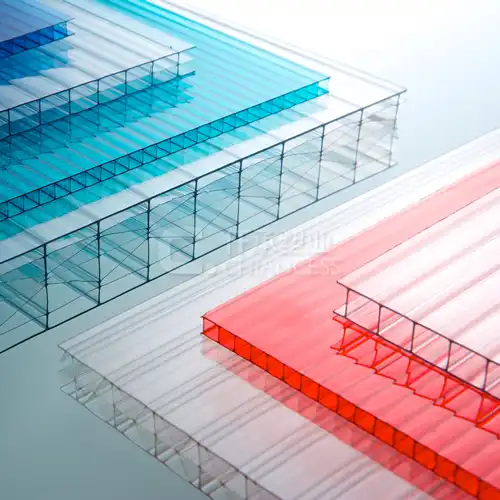

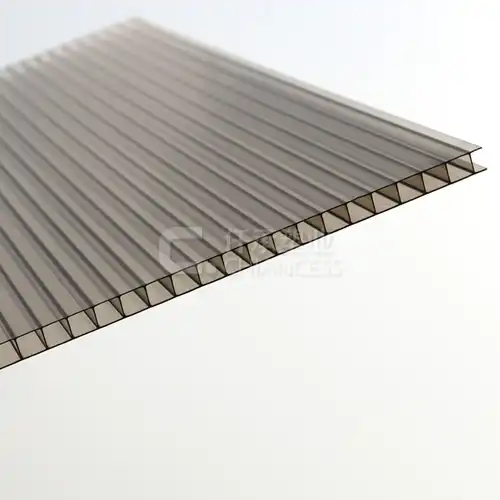

Polycarbonate is a thermoplastic polymer that is widely used in various industries due to its high impact resistance and optical clarity. It is used in applications ranging from eyewear lenses to greenhouse panels and even in the automotive industry. Tinting polycarbonate can serve several purposes, including reducing glare, enhancing aesthetic appeal, providing UV protection, and improving privacy.

Tinting polycarbonate can transform it into a functional and decorative element. For instance, tinted polycarbonate sheets are often used in construction for roofing and windows, offering both protection and a modern look. Additionally, it lenses are popular in eyewear, providing comfort and protection to the eyes by filtering out harmful UV rays.

How to Tint Polycarbonate: Methods and Techniques

Tinting polycarbonate involves several methods, each suited for different applications and desired outcomes. Here are the most common techniques:

Dyeing Process

The dyeing process is a popular method for tinting polycarbonate, especially for smaller items like eyewear lenses. This process involves immersing the polycarbonate in a dye solution at a specific temperature. The dye penetrates the surface of the polycarbonate, creating a tinted effect. The depth and intensity of the tint can be controlled by adjusting the concentration of the dye and the immersion time.

Coating Application

Another method of tinting polycarbonate is by applying a tinted coating. This technique is commonly used for tinted polycarbonate sheets or panels. The coating can be sprayed or rolled onto the surface, creating a uniform tinted layer. This method allows for a wide range of colors and finishes, from matte to glossy. Coated polycarbonate is often used in architectural applications, providing both aesthetic and functional benefits.

Tinted Films

Applying tinted films is a versatile and non-permanent method of tinting polycarbonate. These films are adhesive-backed and can be easily applied to the surface of the polycarbonate. Tinted films come in various shades and can offer additional benefits such as UV protection and glare reduction. This method is particularly useful for applications where the tint may need to be changed or removed later.

Benefits of Tinting Polycarbonate

Tinting polycarbonate offers several advantages, making it a popular choice for various applications. Here are some of the key benefits:

UV Protection

One of the primary benefits of tinting polycarbonate is UV protection. Tinted polycarbonate sheets can block harmful UV rays, protecting both the material itself and the users. This is particularly important for applications like eyewear lenses and greenhouse panels, where UV exposure can cause damage over time.

Glare Reduction

Tinted polycarbonate can significantly reduce glare, making it ideal for applications such as automotive windows and sunglasses. By reducing glare, tinted polycarbonate enhances visibility and comfort, especially in bright conditions.

Aesthetic Appeal

Tinting polycarbonate can enhance the visual appeal of a product or structure. Tinted panels and sheets are available in a wide range of colors and finishes, allowing for creative and attractive designs. This is especially beneficial in architectural applications, where aesthetics play a crucial role.

Privacy and Security

It can provide an additional layer of privacy and security. Tinted windows and panels obscure the view from outside, protecting the interior from prying eyes. This makes it a popular choice for commercial buildings and residential properties. Energy Efficiency

In architectural applications, the product can contribute to energy efficiency. By reducing the amount of heat and light entering a building, it can help maintain a comfortable indoor temperature and reduce the need for air conditioning.

Applications of Tinted Polycarbonate

It is used in a variety of applications across different industries. Here are some of the common uses:

Eyewear

One of the most popular applications of it is in eyewear lenses. Tinted lenses provide UV protection, reduce glare, and enhance visual comfort. They are widely used in sunglasses, safety glasses, and prescription glasses.

Automotive Industry

In the automotive industry, it is used for windows, sunroofs, and headlight covers. Tinted automotive windows offer privacy, reduce glare, and protect the interior from UV damage. Tinted headlight covers enhance the aesthetic appeal of the vehicle.

Construction and Architecture

In construction and architecture, it is used for roofing, windows, and skylights. It panels provide both functional and aesthetic benefits, such as UV protection, energy efficiency, and an attractive appearance.

Greenhouses and Agriculture

The product is also used in greenhouses and agricultural applications. Tinted panels can help regulate light and temperature, creating an optimal environment for plant growth. They also provide UV protection, which is beneficial for both plants and equipment.

Consumer Products

Tinted polycarbonate is used in various consumer products, including electronics, sporting goods, and home décor. For example, tinted polycarbonate is used in smartphone cases, providing both protection and a stylish look.

Factors to Consider When Tinting Polycarbonate

When considering tinting polycarbonate, several factors need to be taken into account to achieve the desired outcome. Here are some important considerations:

Type of Polycarbonate

Different types of polycarbonate may react differently to tinting methods. It's important to choose the appropriate type of polycarbonate for the intended application and tinting process. For example, UV-stabilized polycarbonate may be more suitable for outdoor applications.

Desired Tint Color and Intensity

The desired color and intensity of the tint will influence the choice of tinting method. Dyeing and coating methods offer a wide range of colors and intensities, while tinted films provide flexibility and ease of application.

Application Environment

The environment in which the product will be used is another important consideration. For outdoor applications, UV protection and weather resistance are crucial. For indoor applications, factors like glare reduction and aesthetics may be more important.

Cost and Durability

The cost and durability of the tinting method should also be considered. Dyeing and coating methods may offer longer-lasting results, while tinted films may be more cost-effective and easier to replace.

Research and Developments in Tinted Polycarbonate

Ongoing research and development in the field of polycarbonate tinting are leading to new and improved methods and applications. Advances in dye formulations, coating technologies, and film materials are enhancing the performance and versatility of it.

Innovative Dye Formulations

Researchers are developing new dye formulations that offer better color stability, UV protection, and environmental resistance. These innovations are expanding the range of applications for it, making it more durable and reliable.

Advanced Coating Technologies

Advancements in coating technologies are improving the application process and performance of it coatings. New coatings offer enhanced adhesion, durability, and resistance to scratching and weathering, making them suitable for a wider range of applications.

High-Performance Tinted Films

The development of high-performance tinted films is providing more options for temporary and reversible tinting solutions. These films offer improved UV protection, glare reduction, and aesthetic appeal, making them a popular choice for various applications.

Sustainable Solutions

Sustainability is a growing focus in the development of the products. Researchers are exploring eco-friendly dye and coating formulations, as well as recyclable tinted films, to reduce the environmental impact of polycarbonate tinting.

Conclusion

Tinting polycarbonate is a versatile and beneficial process that can enhance the functionality and aesthetics of the material. Whether for UV protection, glare reduction, privacy, or aesthetic appeal, it offers a wide range of applications across various industries. By understanding the different tinting methods, benefits, and considerations, you can make informed decisions about how to use it in your projects.

For more information about it and its applications, please contact us at simon@chiancess.com.

references

1. Gogos, A., & Tarantili, P. A. (2018). Thermoplastic Polymers and Materials. In Encyclopedia of Polymer Applications (pp. 1047-1061). CRC Press.

2. Haq, M. I. U., Islam, S. S., Akhtar, K., & Algahtani, F. (2021). Tinted Polycarbonate for Glare-Free Lenses: A Comparative Study. Polymer Engineering & Science, 61(9), 2612-2621.

3. Matuschek, G., & Schwob, T. (2019). Transparent Solar Control Coatings for Polycarbonate. International Journal of Materials Research, 110(5), 558-564.

4. Chiu, W. S., Yip, M. C., Lam, C. W., & Lo, S. L. (2017). Dyeing of Polycarbonate in Supercritical Carbon Dioxide for Automotive Glazing. Industrial & Engineering Chemistry Research, 56(6), 1493-1502.

5. Han, J., Tan, Y., Fang, H., & Zou, X. (2020). The Development of Tinted Polycarbonate Films with UV-Blocking Properties for Greenhouse Applications. Journal of Polymers and the Environment, 28(8), 2036-2045.

.webp)